It can lower vehicle surface temperature by up to 42°F, reducing AC consumption and saving on fuel, too.

In 2020, a team of scientists at Purdue University developed the world’s whitest white — a paint color so white it could reflect 98.1% of the sunlight that hits it. That paint formula was designed for hard surfaces like rooftops and pavement, to lower the surface temperature and help combat the urban heat island effect. Then NASA enquired about a space-friendly version of that paint: It had to reflect just as much sunlight, but it also had to be thinner in an industry where it costs $2,720 per kilogram to launch a payload into space (on a SpaceX Falcon 9).

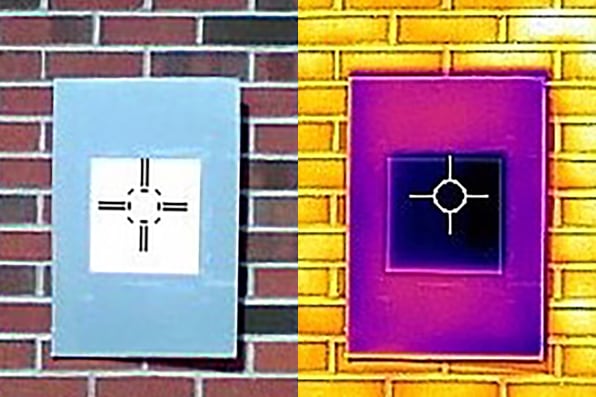

The same scientists at Purdue University have now developed whitest white 2.0 and the research has been published in the journal Cell Reports Physical Science. The new version is 2.5 times thinner than the original, 80% lighter, and reflects 97.9% of the sun, or just a smidge less than its thicker counterpart. And while it could eventually be spray- painted on a spacecraft, it’s also thin enough to coat cars, planes, and refrigerator trucks, where it could lower surface temperature by up to 42 degrees Fahrenheit. As a result, it could help reduce AC consumption in vehicles, and since these air- conditioning systems consume fuel, it could help save on gas, too.

You may not think about it much, but paint comes in different thicknesses. Commercial paint like the one on your walls is about 200 microns thick, or 0.2 millimeters. The industry standard for cars is about 120 microns, which helps prevent cracks but also saves on weight. Car manufacturers, EV ones in particular, have struggled with weight for decades (cars are 25% heavier today than they were in 1990). By comparison, the original “whitest white” was 400 microns, while the thinner version is 150 microns. Except you can’t just add a thinner and achieve the same cooling results, so the scientists had to come up with a brand-new ingredient.

Enter boron nitride, a chemical compound most often used as an additive in lubricants. As Xiulin Ruan, a professor of mechanical engineering at Purdue University who produced the paint explains, the boron and nitrogen atoms that make up boron nitride are lighter than calcite, the key ingredient in the previous formula. (This explains why the paint is 80% lighter even though it’s 2.5 times thinner.)

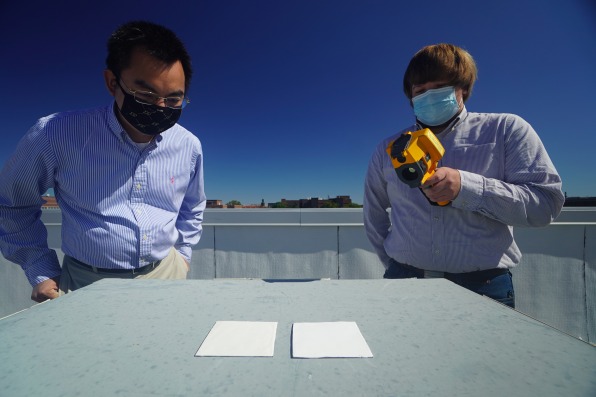

[Image: Jared Pike/Purdue University]

The paint still needs to go through a series of tests, and the team needs to minimize the use of volatile organic compounds, or VOCs, which are toxic chemicals that have been linked with asthma and greenhouse gas emissions, but Ruan believes that the paint will be ready to be commercialized in the next two to three years. Afterward, he envisions a whole world of possibilities that extend well beyond the transport industry—namely clothing, shoes, and even portable electronics, like your smartphone. “Our core invention is the pigment, so it could be incorporated into paint, or inside textile fibers,” he says. “It can be sprayed, it can be brushed, it can be used on a roller.”

When it comes to the fashion industry, of course, the main advantage would be the bright white color (and the fact that a thinner layer of paint on a shoe is less likely to crack, says Ruan). But the paint’s cooling properties would be put to much better use on the roof of a car, a refrigerator truck, or on the surface of spacecraft like the Parker Solar Probe currently hurtling towards the Sun.Such perks, however, come at a cost. While the paint is 80% thinner, Ruan envisions it will be about 10 times more expensive than the original, simply because boron nitride is produced synthetically and therefore more expensive than calcium carbonate (calcite) — an abundant material found in limestone and chalk. “This new version will be more suitable for applications where cost is less sensitive but weight and thickness are important,” he says.

—

This article first appeared www.fastcompany.com

Seeking to build and grow your brand using the force of consumer insight, strategic foresight, creative disruption and technology prowess? Talk to us at +971 50 6254340 or engage@groupisd.com or visit www.groupisd.com/story