As NASA ramps up plans for lunar exploration, Bjarke Ingels Group releases a concept for moon habitats that can be 3D-printed from Earth.

Humans are going back to the moon. NASA has announced that a crewed mission will land on the moon by 2024, and that “sustained lunar exploration” will be possible by 2030. When these future moon explorers get there, they’ll need a place to stay.

Building with moon dust is less improbable than it might seem. Common cinderblocks are little more than sand and glue, and advances in additive manufacturing have shown that 3D printers can be used to make habitable structures. These advancements are partly why NASA is funding the construction technology startup Icon, which has developed a 3D printer capable of constructing housing at scale (a project that won Fast Company’s 2020 Innovation by Design Awards). Based in Austin, Icon was a finalist in NASA’s 3D-Printed Habitat Challenge.

To figure out what exactly this 3D printer can and should build on the moon, Icon has announced a partnership with SEArch+, an architecture firm that has worked with NASA on human-centered designs for space exploration, and the Bjarke Ingels Group, one of the world’s most prominent architecture firms. With projects like a ski-slope topped waste-to-energy plant in Copenhagen, a pyramid-like apartment building in Manhattan, and the Lego House museum in Billund, Denmark, BIG is known for audacious and crowd-pleasing architecture.

When Icon CEO Jason Ballard met Ingels at South By Southwest in 2019 and gave him a tour of the home his company had 3D-printed in Austin, he knew he had found an ideal partner for applying Icon’s technology off-world. “This is an incredible architectural and construction achievement if we’re able to do this, and we didn’t want it to just be a mound of dirt. There’s a significance to this,” he says. “So the idea with this partnership between Icon and BIG is that it’s really robust from a science and engineering perspective, but also worthy of being humanity’s first home on another world.”Ingels says the designs his firm has developed for this project came about through detailed research into the lunar environment, but also close interaction with Icon to understand how its technology would (or would not) be able to build the kinds of moon-worthy architecture BIG could come up with. “Many of the early assumptions we came up with turned out to be not entirely true once we got into the nitty-gritty,” Ingels says. “It became this exploration process back and forth, slowly evolving or uncovering what the lunar vernacular ends up looking like.”

Like the vernacular architecture that developed among Earth-based civilizations over generations and millennia, the architecture of the moon will be determined more by materials and conditions than aesthetics. Ingels points to moon days and nights that last the equivalent of two Earth weeks, extreme heat and cold, radiation, and a regular onslaught of meteorites. “Before we even start adding any kind of choice or sensibility, it starts suggesting certain forms over others,” he says.

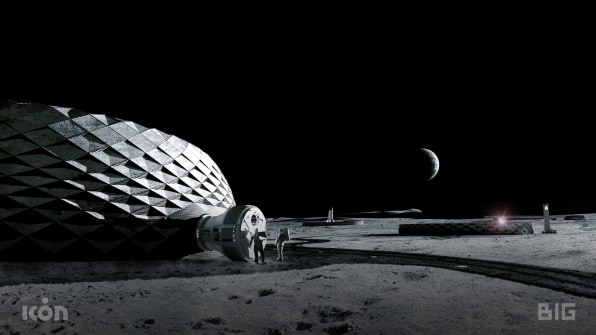

The designs that BIG developed are donut-like igloos, with waffled exteriors that provide both structure and protection. Ingels says they hit a precise ratio between contained volume and outer surface area to account for the differential between the moon environment and the indoor atmosphere people need to survive. “It’s almost like a balloon that wants to burst,” he says. “This kind of language started emerging that, when you look at it, you could suspect is ornamental but it’s 100% functional.”

And pragmatic. It’s all been carefully designed to be buildable with Icon’s printing technology, which is now being engineered to work with the dusty regolith of the moon’s surface. And unlike the three people currently required to operate the 3D-printing system, the moon-based printer is being configured to operate autonomously, constructing all of a moon base’s structures on its own, with remote instructions from another base or even on Earth.“In many ways, we have to develop the entire industry,” Ingels says. “When we design something on Earth, we have this global catalog of stuff. Whereas here we have to do everything in situ [on the moon]. And the more that the same machinery can deliver multiple parts, the more powerful and the closer we get to full autonomy for a sustained and sustainable human presence on the moon and elsewhere.”

That will require not only donut-shaped human habitats, but also less flashy elements like landing and takeoff pads and roads. “The habitats are the most exciting and probably charismatic part of the project, but there’s this whole layer of infrastructure that has to go in,” says Ballard.Ballard says that while Icon had off-world architecture as a goal from its founding in 2018, this project may actually have broader relevance for how things get built back here on Earth. “By pushing the boundaries on the reliability, the resilience of the actual engineering and the machinery, by pushing the limits of autonomy, which we’re forced to do by thinking about the moon, it’s actually going to make construction on Earth even faster, even cheaper,” he says.

BIG’s designs for the moon may also have an influence on architecture here, Ballard says. “The result is incredibly elegant. I can’t imagine that some of this space-age architecture doesn’t cross-pollinate into what’s possible in Earth-based architecture.”

This article first appeared in www.fastcompany.com

Seeking to build and grow your brand using the force of consumer insight, strategic foresight, creative disruption and technology prowess? Talk to us at +971 50 6254340 or mail: engage@groupisd.com or visit www.groupisd.com/story